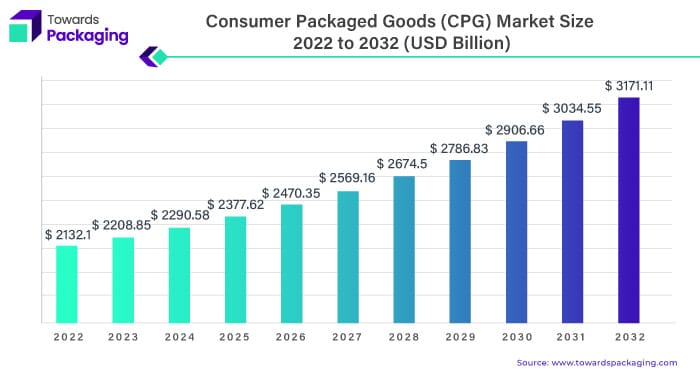

The global consumer packaged goods market (CPG) size is expected to grow from USD 2,132.1 billion in 2022 and estimated to reach USD 3,171.11 billion by 2032, says a report by Towards Packaging. That means growing at a 4.1% CAGR from 2023 to 2032. To keep up that growth rate, optimizing productive capacity and reducing waste are crucial for contract manufacturing organizations (CMOs) looking to enhance profitability, sustainability, and client satisfaction. Executives in this sector face the dual challenge of maximizing efficiency while minimizing waste, a balance that is essential for staying competitive and attractive to clients. Here are some strategies that can help achieve these goals.

1. Implement Lean Manufacturing Principles

Lean manufacturing is centered around the elimination of waste within a manufacturing system without sacrificing productivity. It involves methods that aim to produce higher quality goods at the lowest possible cost by minimizing waste and reducing time by focusing on continuous improvement. Techniques such as Kaizen, 5S, and value stream mapping are essential tools in the lean arsenal that can dramatically improve the efficiency and flexibility of production processes.

2. Adopt Advanced Manufacturing Technologies

Investing in advanced manufacturing technologies such as automation, robotics, and AI-driven analytics can significantly enhance production capacity. These technologies not only speed up the production process but also increase accuracy, reduce human error, and lower the likelihood of producing defective products which, in turn, decreases waste. For instance, predictive maintenance technologies can anticipate equipment failures before they occur, thus avoiding unexpected downtime and costly disruptions.

3. Enhance Supply Chain Management

Optimizing the supply chain is critical for reducing material waste and ensuring that production lines operate smoothly without interruptions. Techniques like Just-In-Time (JIT) inventory can help CMOs reduce waste associated with excess inventory and storage costs. Additionally, building strong relationships with suppliers ensures a reliable flow of materials and reduces the risks associated with overstocking and underutilization.

4. Utilize Capacity Planning Tools

Effective capacity planning ensures that manufacturing facilities are not overused or underutilized. Utilizing sophisticated capacity planning software helps in accurately forecasting demand and adjusting production schedules accordingly. This not only maximizes throughput but also ensures that resources are allocated efficiently, thereby minimizing waste.

5. Conduct Regular Training and Development

Human error is a significant contributor to waste in manufacturing. Regular training and development sessions for employees can lead to better operation of machinery, fewer operational errors, and a more competent handling of materials. Additionally, empowering employees to identify inefficiencies and suggest improvements can foster a proactive culture of continuous improvement.

6. Implement Sustainable Practices

Adopting sustainable manufacturing practices can lead to significant reductions in waste. This includes recycling scrap material, using environmentally friendly materials, and reducing energy consumption. Such practices not only reduce the environmental impact but also improve the organization’s image and appeal to clients who are increasingly concerned about sustainability.

7. Monitor, Measure, and Improve

Finally, the ability to effectively monitor, measure, and improve manufacturing processes is essential. Implementing comprehensive tracking systems and key performance indicators (KPIs) allows executives to get real-time data on every aspect of production. This data is crucial for identifying waste areas, understanding capacity limits, and making informed decisions about process improvements.

GrowinCo’s Available Capacity Listing Feature

To further support the optimization of productive capacity, GrowinCo introduces its Available Capacity Listing feature. This innovative marketplace platform allows companies to list their available production capacities, making them visible to other companies in need of expanding their production capabilities. This feature not only helps in better utilization of manufacturing resources but also facilitates business growth by connecting companies with potential partners who can make immediate use of underutilized capacities. Through GrowinCo’s marketplace, CMOs can ensure their production lines are always running at optimal levels, maximizing efficiency and minimizing waste.

For contract manufacturing organizations, optimizing productive capacity and reducing waste are not just about improving margins but also about enhancing competitive advantage and customer satisfaction. By implementing these strategies and leveraging platforms like GrowinCo’s Available Capacity Listing feature, CMO executives can ensure their facilities run at optimal efficiency, produce less waste, and are positioned well for growth in a demanding market.