You may have the best product in the world — but if it takes too long to reach the shelf, someone else will beat you to it.

In the consumer packaged goods (CPG) industry, the time between concept and execution defines who leads and who follows. Yet innovating, scaling, and launching quickly requires more than goodwill: it demands an agile, flexible, and sustainable production infrastructure.

This is where co-manufacturing shifts from a tactical fix to a strategic pillar for efficiency, innovation, and cost reduction. Whether to test a new SKU or increase capacity without heavy capital expenditure, it offers the fastest route from concept to consumer.

In this article, you’ll learn how co-manufacturing is shaping the future of production in the CPG sector — bridging innovation, market intelligence, operational efficiency, and sustainability.

The new logic of “producing fast”

In recent years, the consumer goods sector has undergone a profound transformation: the rigid, linear production model has given way to leaner, more flexible, and collaborative strategies. Product development cycles have shortened. Personalization has become the norm. And consumer response times must be nearly instantaneous.

According to Deloitte, 83% of CPG executives see production and distribution agility as critical for innovation. The same report highlights strategic outsourcing as one of the key ways to shorten time-to-market without sacrificing margin or quality.

How co-manufacturing solves both sides of the equation: cost and agility

The logic behind co-manufacturing is simple: instead of internalizing every production stage, brands hire specialized industrial partners to handle part or all of their product manufacturing.

This model delivers clear benefits:

-

Reduced fixed costs for infrastructure, machinery, and technical staff;

-

Access to operational technologies and processes without upfront CAPEX;

-

Immediate scalability—whether for demand spikes or launching new SKUs;

-

Accelerated product development, with facilities ready to test, adapt, and launch.

Co-manufacturing enables brands to stay focused on their core strengths: branding, sales channels, and customer relationships — while delegating production to experts.

How Unilever leveraged co-manufacturing to scale sustainable product lines

One of the most notable recent examples of co-manufacturing driving sustainable innovation comes from Unilever. To fast-track launches of concentrated products and recyclable packaging in personal care, the company partnered with co-manufacturers across Europe and Latin America. This enabled:

-

Localized small-scale production, lowering logistics costs and carbon emissions;

-

Faster market testing in regional channels;

-

Limited editions to measure market fit before scaling.

According to Unilever’s Sustainability Report, this approach cut development time for sustainable products by 35%.

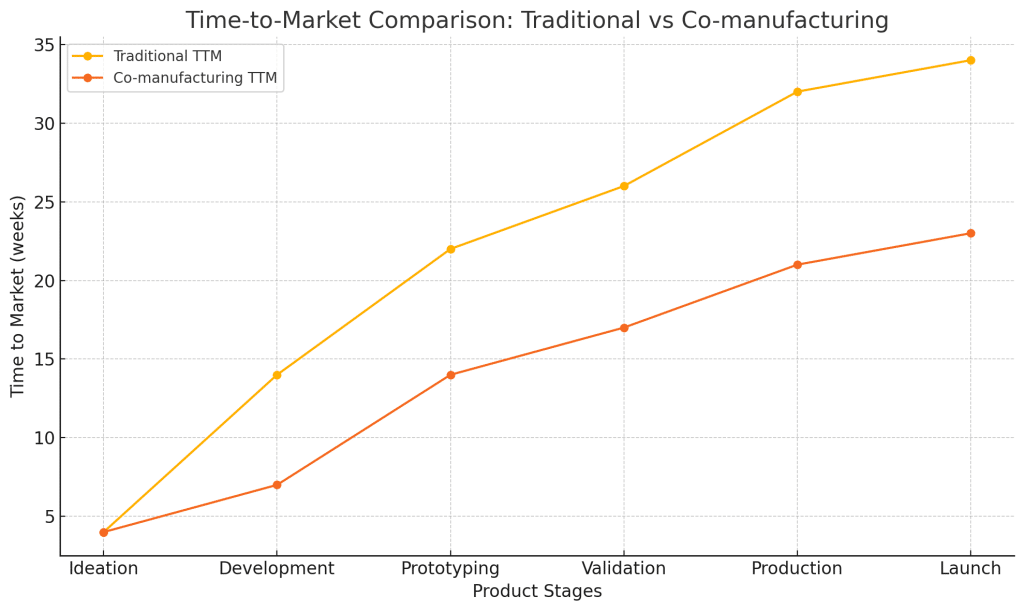

The timeline below shows how co-manufacturing can reduce time-to-market by up to 36%, making it invaluable where speed is critical.

The role of co-manufacturing in CPG innovation

→ how does this happen?

- industrial innovation labs: many co-manufacturers offer joint R&D, enabling brands to test ingredients, processes, and formulas rapidly;

- batch customization: to pilot SKUs for niche audiences or digital channels;

- trend responsiveness: launching a plant-based line or limited summer edition can happen in weeks, not months.

NielsenIQ reports that fast-launch products are up to 2.5x more likely to succeed commercially within the first six months, thanks to capturing trends while they’re still rising.

Sustainability in production: less waste, more efficiency

Another growing benefit is co-manufacturing’s contribution to ESG goals.

Producing locally, optimizing lines, and scaling to real demand allows companies to:

- Reduce raw material and energy waste;

- Lower transportation volume and emissions;

- Optimize packaging and processes for minimal environmental impact.

This approach aligns with the emerging “circular production” trend in CPG: manufacturing based on demand with the lowest environmental footprint.

Who benefits from co-manufacturing?

| company profile | key benefits |

|---|---|

| large corporations/brands | agility to test new SKUs, serve regional channels, and support ESG strategies |

| medium-sized companies | scale without CAPEX, access to technology and qualified suppliers |

| suppliers and manufacturers | monetize idle capacity, gain new contracts and categories |

By combining cost reduction, flexibility, and innovation, co-manufacturing bridges operational efficiency and growth velocity.

How to choose a reliable co-manufacturing partner

The right partner is essential for success. Key considerations include:

- Technical capacity and proven track record

- Certifications required by the sector (e.g., FDA, ISO, HACCP)

- Flexibility in batch sizes and customization

- Strategic location for logistics

- Transparency and operational governance

Specialized platforms like GrowinCo. simplify this process, connecting brands to validated co-manufacturers by category, region, and service type.

Growinco. as a catalyst for innovation and efficiency

GrowinCo. is the platform that links brands with trusted, specialized, and strategically located co-manufacturers. Using market intelligence, structured data, and technical curation, it facilitates:

- Connections between companies needing fast production and partners with available capacity;

- Creation of new production partnerships with lower risk and faster negotiation;

- Building more sustainable, local, and efficient supply chains.

Whether launching a new product, testing a market, or scaling a category, GrowinCo. accelerates processes and reduces complexity — all focused on innovation, efficiency, and cost savings.

The future of production is collaborative, agile, and smart

As the CPG market evolves, co-manufacturing cements itself as the critical link between innovation and execution. It empowers brands to keep pace with fast-changing consumers, respond swiftly to trends, and operate efficiently without compromising quality or control.

Reducing costs, accelerating time-to-market, and maintaining competitiveness are no longer conflicting goals — they’re achievable when production is designed collaboratively.

With intelligent platforms like GrowinCo., this journey becomes even more strategic, accessible, and sustainable.